Conveyors should be modular, reliable, and intuitively assembled.

These conveyor systems are composed of modular sections that can be rearranged to accommodate changing business needs.

For example, implementing a new packaging machine may require a conveyor to be rerouted in a new direction. I designed the conveyor sections to be unopinionated in their relationship to one another, allowing us to reconfigure them quickly and easily. The company had purchased conveyors from 3rd party vendors in the past, but found their machines to be either exorbitantly expensive or unreliable. We therefore set out to build our own machines that would be comparatively inexpensive without sacrificing quality and reliability.

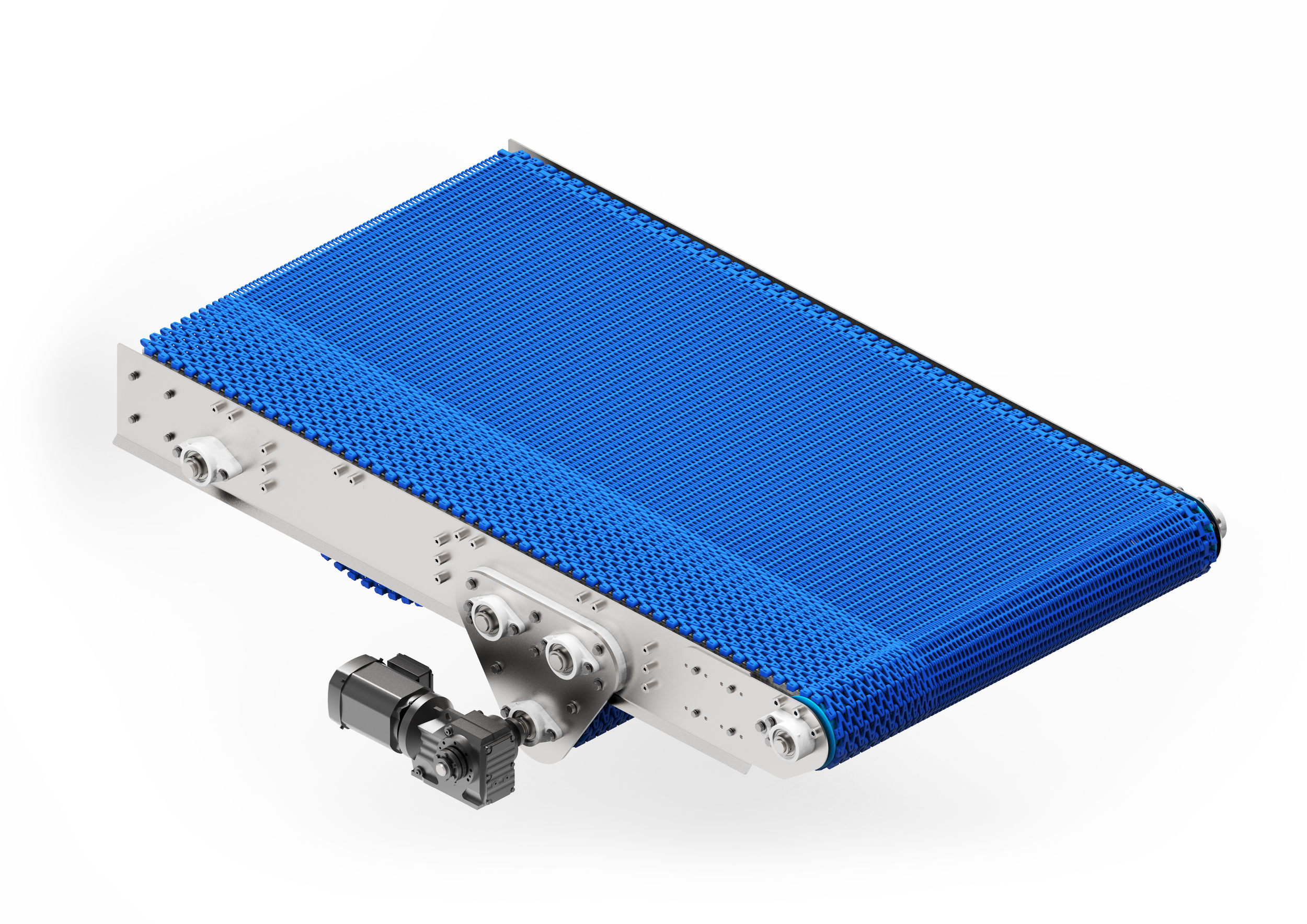

Each conveyor has a drive section. This section pulls plastic belting through the system.

Each conveyor and subsequent machine needs to move cookies at the same or gradually faster pace to avoid a pileup. (You really don’t want a batch of 90,000 hot cookies piling up!) To that end, a motor spins a shaft, fitted with sprockets, that in turn drives the belt. The RPM of the motor multiplied by the circumference of these sprockets determines the speed that cookies will move.

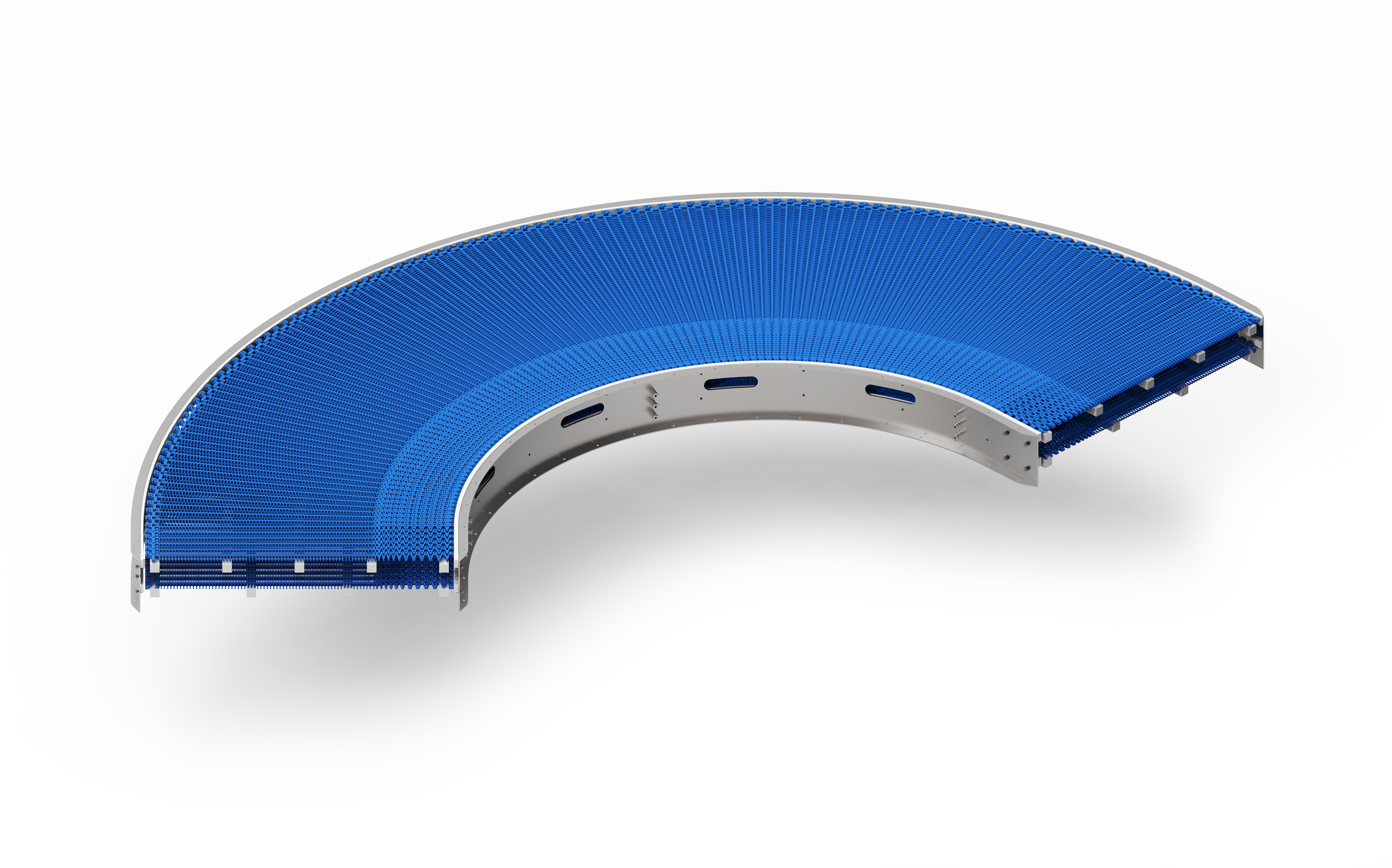

Radial sections presented fabricators with unique challenges.

It is important that conveyors turn along a gradual, smooth, calculated curve. If there are misalignments between the concentric metal frames, the belt has a tendency to “jump” out of place, causing a serious breakdown in the system.

To construct the stainless steel frame, we began by laser cutting the sidewall and sending it through a metal roller to get the approximate radius bent into it. Once the sidewall has been rolled, it is then welded to laser cut keys. Essentially, these keys ensured that the sidewall matched the intended curve with exactness.

I like to make welders happy - it was exciting when a design in the CAD model made their work easier, as these keys demonstrated.

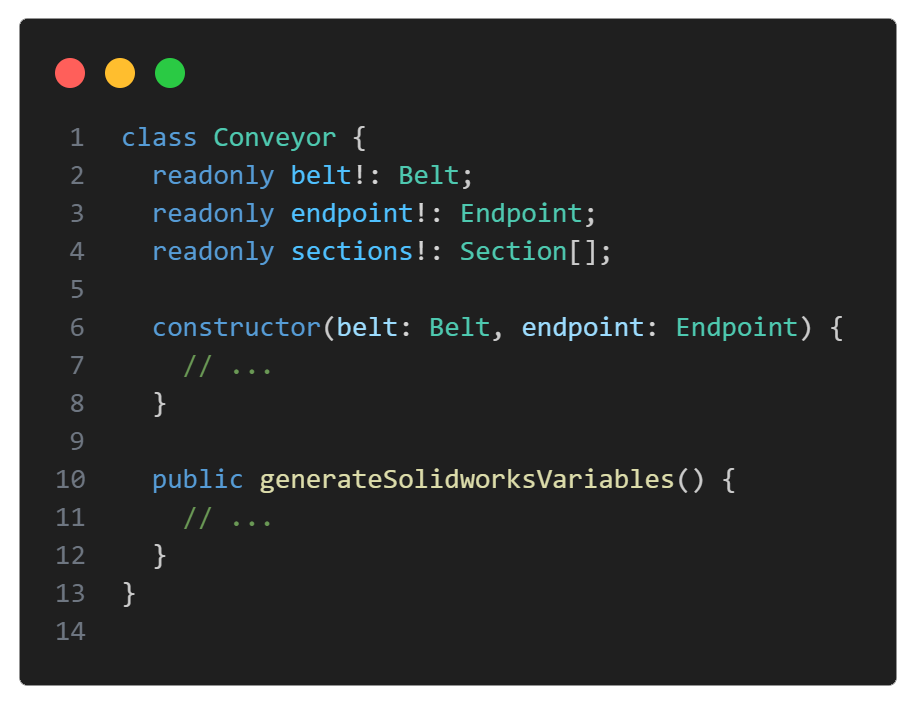

As I continued to build new conveyors, it became apparent that software could automate the design process.

After designing and building about 5 conveyor systems, I was intrigued that each one embodied the same underlying design logic. I could see that independent of its size and route, each conveyor could be conceptualized as a hierarchal assembly of logical decisions.

For example, the belt of a conveyor constrains the radial sections in how tightly they can turn. In other words, there is a logical dependency between the Belt and the Radial Section.

I began representing these dependencies and relationships in code (TypeScript) rather than in CAD (Solidworks).

Shifting the logical decisions to code rather than CAD allowed me to forego the gymnastics of top-down design in Solidworks. This dramatically increased the speed that I could produce new variants based on changing inputs, especially when working with large, nested assemblies.

(Code abbreviated)